RESEARCH

- Research Center

-

Laboratory Information

- Bio-Medical Nanochemistry Lab

- Computational Medicine Lab

- Data Engineering Lab

- Distributed Computing Lab

- Energy Electrochemistry Lab

- Future Communications & Systems Lab

- Knowledge Service Consulting Lab

- Applied Laser Technology Lab

- Nano Systems Lab

- Networked Systems Lab

- Networking and intelligent Processing Lab

- Neural Engineering and Control Laboratory(NEC)

- Vibration & Measurement Lab

- Virtual Manufacturing & Intelligence, Optimization Lab

- Wireless & Emerging Network Systerm Lab

- Nano & Particle Technology Lab

- Thermal Fluid System Laboratory

- Sustainable Materials and Process Design Lab

- Thermal-Structural Analysis and Aero-Heating Test Lab

- Advanced Surface Devices Lab

- Research Articles

- Research Project

Introduction

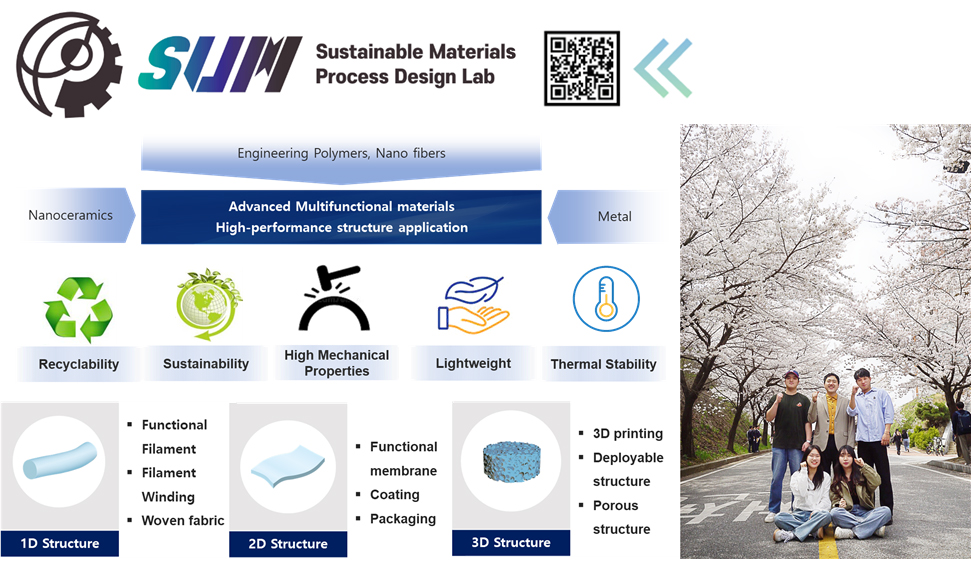

SUM LAB (Sustainable Materials and Process Design Laboratory) research eco-friendly and recyclable sustainable materials, and designs functional composite materials using them. Additionally, the lab develops optimized processes suitable for manufacturing 1D fiber, 2D film, and 3D structures through various material processes and analysis to efficiently produce high-quality multi-functional products. Our laboratory aims to contribute to the advancement of future industries and realize a sustainability through these research activities.

- Research on Sustainable Materials and Functional Composites

- Eco-friendly high-strength mechanical materials based on nanocellulose

- Reusable high-strength mechanical materials based on nanoaramid

- Functional composites utilizing carbon, metal, and ceramic nanomaterials - Research on Structural Fabrication and Process Optimization.

- Nanomaterial and nanocomposites fabrication processes

- 1D structures: wet spinning, dry spinning, and drawing processes

- 2D structures: film casting, roll-to-roll, and pressing processes

- 3D structures: 3D printing, molding, and CNC machining

- Nano and micro surface patterning processes - Research on Advanced Industrial Application

- Manufacturing of lightweight, high-strength mechanical components and structures

- Fabrication of wearable devices and bio-scaffolds

- Manufacturing of energy harvesting, sensors & actuators based on functional nanocomposites.

Contact

- Prof. Hyun Chan Kim (hyunckim@kumoh.ac.kr)

- LinkedIn: www.linkedin.com/in/hyunckim

- https://sum.kumoh.ac.kr

Recent Project

- National Research Foundation of Korea, "Development of Machine Component Manufacturing Technology Using Sustainable High-Strength Nano Polymers", 2024 ~ Current

- National Research Foundation of Korea, "High Specific Strength Nanocomposite based on Cellulose Nanofiber and Aramid Nanofiber", 2021~2022.

Recent published Journal Articles

- Room temperature 3D printing of high-temperature engineering polymer and its nanocomposites with porosity control for multifunctional structures. Composites Part B: Engineering 279 (2024): 111444. (IF=13.1)

- Alignment Controlled Aramid Nanofiber‐Assembled Films. Advanced Functional Materials (2024): 2315422. (IF=19.924)

- Ultra‐high toughness fibers using controlled disorder of assembled aramid nanofibers. Advanced Functional Materials 33,4 (2023): 2208661.(IF=19.924)

- Never-dried aramid nanofibers dispersed in organic solvents for nanofiber-reinforced composites. ACS Applied Nano Materials 6, 2 (2023): 832–837.(IF=6.14)

- Additive Manufacturing of High-Temperature Thermoplastic Polysulfone with Tailored Microstructure via Precipitation Printing. ACS Applied Materials & Interfaces 15, 38 (2023): 45270-45280. (IF=9.5)

- Transparent and flexible photon sieve made with cellulose nanofiber by micro-nano structure molding. IJPEM-GT 9,4 (2022): 1165-1175.(IF=4.66)

- Electric field-assisted wet spinning to fabricate strong, tough, and continuous nanocellulose long fibers. Cellulose 29,6 (2022): 3499-3511.(IF=6.123)

Call for Ph.D. and M.S. Students

- A positive mindset and team-oriented leadership

- Open to diverse cultures

- Creative, responsible person

- Passions in the study and research of nano composites materials and experiments.

- Proficiency in English

Student Benefits

- Tuition free, monthly stipend, international/domestic conference participation, dormitory, Personal desk, etc.